Engineered performance and durability

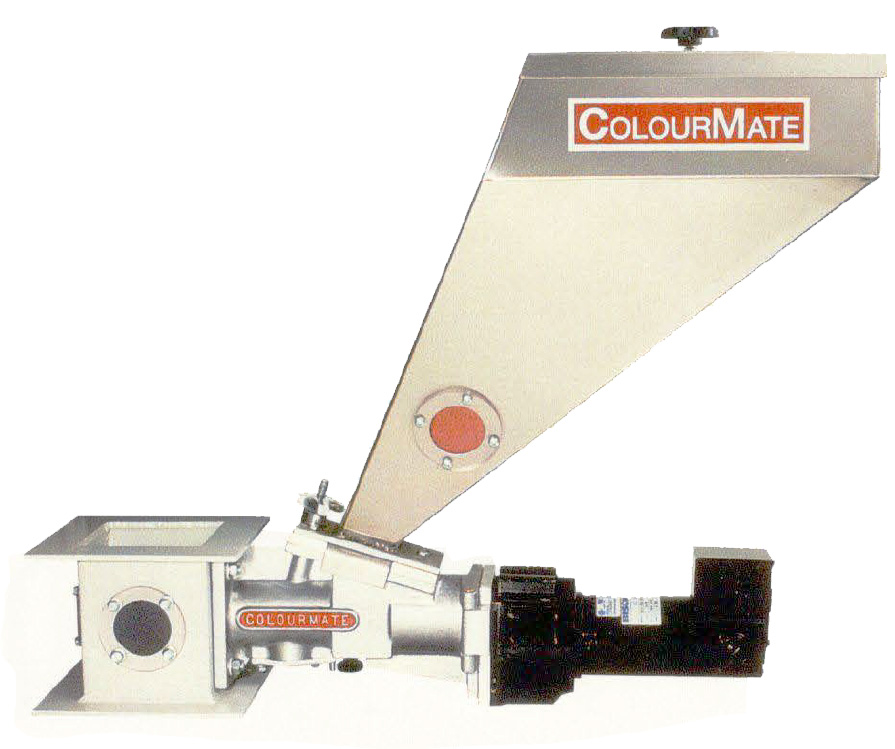

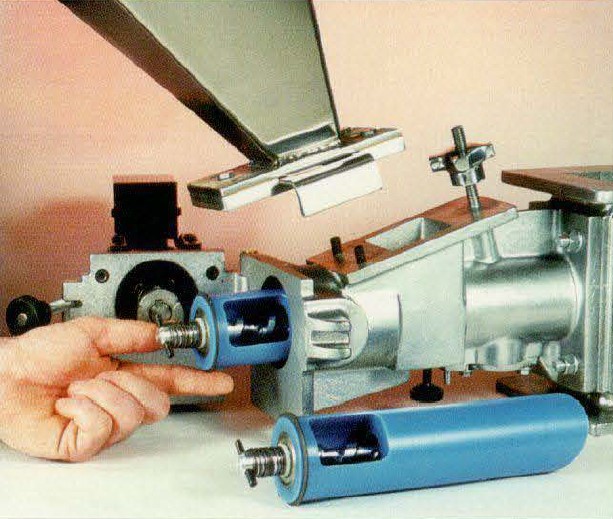

Colourmate takes pride in engineering an additive feeder which provides you with both performance and durability. For

precise "at-the-throat" metering of free flowing additives our feeder cannot be surpassed. The feeder's main body is cast

from rigid yet light weight aluminum alloy. Its removable supply hopper is constructed of durable stainless steel which provides

a non-corrosive base both inside and out. This allows for an operation that runs smoothly while keeping materials free from

contaminants. The feed auger is made from a non-corrosive alloy which conveys the material, uncontaminated, through a

machined nylon barrel. The Coraloy auger and nylon barrel are machined, matched and assembled as an integral unit. The

integral nature of this assembly allows for easy removal and cleaning while maintaining proper auger alignment. The throat

section of the Colourmate additive feeder, fabricated from plated steel, securely carries the weight of any size machine hopper.

Various sizes of throat are available which allows for easy adaptation to most machine throat configurations. The Colourmate

additive feeder is the most versatile "at-the-throat" feeder available as its design offers accurate metering and repeatability

along with the quickest colour changes.

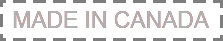

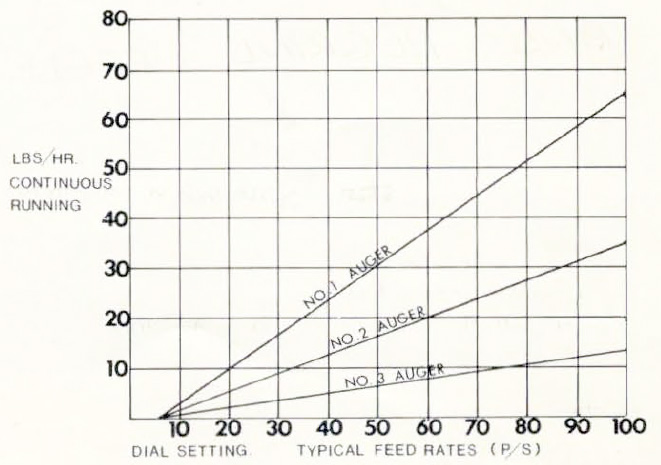

Colourmate's throughput capacity is expanded through the availability of three sizes of interchangeable auger/barrel cartridges. The system may be further expanded by using different gear drive ratios. A sampling port is provided to ensure easy calibration and check of feeder throughput.

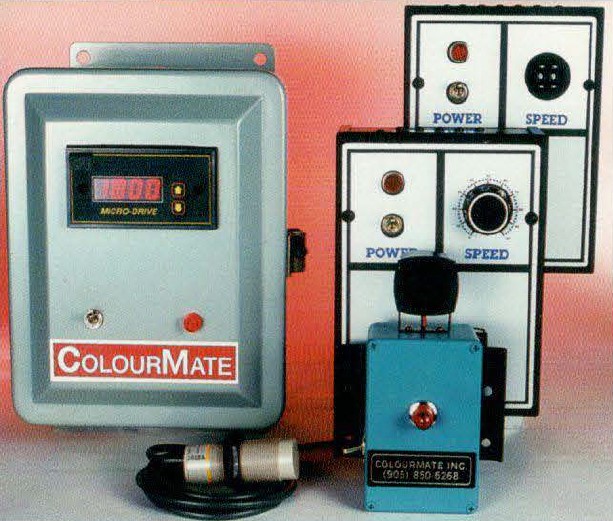

Control-for accuracy and repeatability

The Colourmate control panel is activated by the screw recovery signal on injection or blowmolding machines or the screw R.P.M. on extrusion lines. The standard Thyrister control panel can be remotely mounted and has fine adjustments for acceleration, deceleration, maximum and minimum speeds, current limiting (torque) and I.R. compensation. An isolated signal follower panel is also available. This panel electronically slaves the Colourmate feeder with the processing machine, allowing the actual speed of the extruder screw to control the feeder's output. Optional inductive and volt metering tachometers along with the special speed control potentiometers are also available to complete your control requirements.

From the many gearmotors available, we have chosen a most durable and maintenance free Ya H.P. motor to power our Colourmate feeder. Matched with the control systems we have developed, a perfectly tuned system is completed which offers extreme overall accuracy, unique regulating/controlling linearity and above all repeatability.

Colour changes

Colourmate additive feeders are designed for the practical processor who requires a unit which is reliable, accurate and affords quick and easy colour changes. Colourmate's hopper features an integral material shut-off gate and single hold down knob which assist in the achievement of quick and simple colour changes. The operator need only close this slide shut-off gate and loosen the hold down knob and the supply hopper can be lifted away with its contents. This feature, along with the swing away motor allows easy access to Colourmate's exclusive integral auger/barrel cartridge which may be removed, as a unit, for easy cleaning and quick alignment. Thus, the Colourmate additive feeder is also ideal for reintroducing certain reground plastics. Colour changes don't have to take all day. With the Colourmate feeder, you can be back in business, making a different coloured part within minutes.

The Colourmate advantage

• Add the correct amount of masterbatch' The Colourmate feeder allows the operator to ADD THE ABSOLUTE MINIMUM amount of Masterbatch required to achieve the desired part colour.

• Colourmate ELIMINATES premixed inventories and AVOIDS wastage due to overmixing or human error and SAVES valuable time and space.

• Colourmate ELIMINATES separation caused when vacuum loading premixed plastics.

• Colourmate ELIMINATES labour, equipment and space required for premixing.

• Low cost.

• Minimum maintenance required.

CAN YOU AFFORD TO BE WITHOUT ONE?